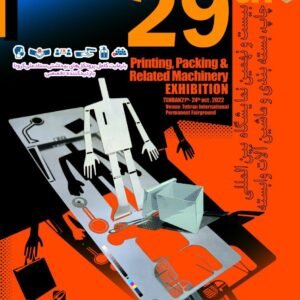

The 29th international exhibition of printing and packaging and related machinery with the presence of Persian Sanat company

October 29 to November 2, 2022 (permanent place of international exhibitions in Tehran) Persian Sanat Baharestan Company has this honor once again. Participate in the