One of the main advantages of buying plastic pallets is recyclability. The materials used in the production of plastic pallets are such that do no harm to the environment. As a result, they can be recycled several times. The process of recycling industrial and plastic pallets is very simple. Plastic pallets that have been damaged due to continuous use and repeated wear can be easily recycled and reused. Customers only need to send their damaged and unusable pallets to our company (Persian Sanat) so that the recycling process can be carried out on them.

Another factor that separates the plastic palette from the wooden palette, and makes them a favorite option, is that they do not require a health certificate or a smooth certificate.

In fact, wooden pallets must be disinfected and fumigated with methyl bromide vapor to obtain these health certificates, while plastic pallets do not require these procedures. Plastic pallets are also higher in terms of price, quality, durability and service life. For this reason, the purchase and sale of plastic pallets have been met with great demand.

Methods of Recycling and Processing Industrial Pallets

Since environmental stability is the main reason for recycling plastic palettes, Persian Sanat also considers the matter to be highly important and always assures its customers that damaged and unusable products will be collected and recycled. In this way, the palettes are returned to the industrial cycle, which not only reduces the production of new plastic products and protects the environment for future generations, but also helps customers to significantly reduce their costs. The recycled products maintain sufficient functionality and can be used effectively in transportation processes.

Plastic pallet recycling can be carried out in several ways:

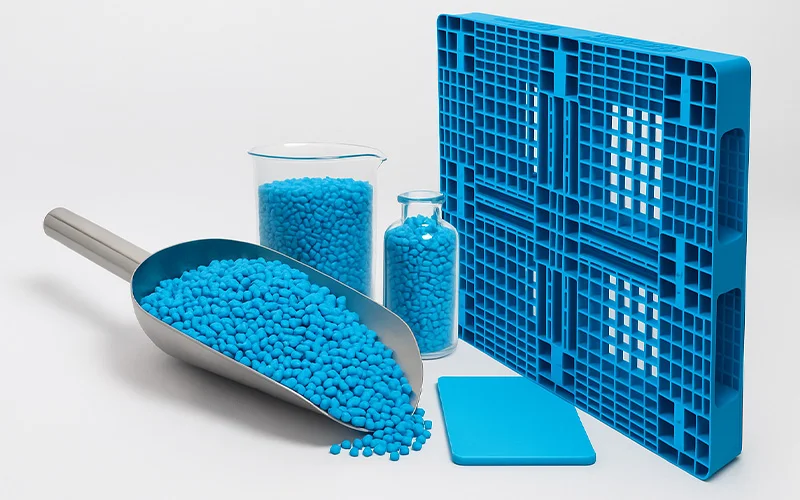

1) Mechanical method: breaking down the pallets into small pieces and converting them into granules.

2) Chemical method: breaking the plastic into its base molecules through chemical reactions so that it can be reused for producing high-quality pallets.

3) Energy recovery method: if recycling or reprocessing is not possible, pallets can be used as fuel for generating heat or electricity.

However, the most reliable, cost-effective, and practical method is mechanical recycling, which we will explain in more detail below.

Industrial Pallet Recycling Machines

With the development of technology and technological advancements, the recycling process of industrial pallets is carried out through specialized machines. It should be noted that the recycling machine is selected based on the type of waste material. For example, since plastic pallets are usually clean and do not require additional washing, relatively simpler machines are used for their recycling. In fact, the choice of recycling equipment largely depends on the type of material. In this way, by recycling industrial pallets, it becomes possible to produce new products from old pallets.

Recycling Process of Industrial Pallets

Before explaining the stages of recycling industrial pallets, it should be noted that all the steps are the same for recycling different types of pallets and do not depend on their type or size.

1. In the first step, after receiving the damaged pallets, the plastic waste is placed on a conveyor belt to begin the recycling process.

2. In the next step, the plastic products are sorted. It is necessary to categorize the pallets and box pallets by color so that different colors are not mixed together.

3. In the third step, an initial cleaning of the pallets is carried out. Although plastic pallets are generally clean, it is better to wash them at this stage to remove any materials that may be stuck to them.

4. In the fourth step, the waste is crushed and ground. Pallets of the same color are placed into the grinding chamber, where powerful shredding machines break them into small pieces, preparing them for the next stage.

5. In the fifth step, the shredded materials are washed with cold water. At this stage, contaminants such as dirt and adhesives are separated in the cold water. If the shredded pallets are washed with hot water, it may alter the shape of the plastic and damage its structure at this stage.

6. The next step involves rinsing and drying the obtained materials. After washing and being cleared of any impurities, the materials are placed in specialized drying machines to ensure no moisture remains on them.

7. In the final step, granulation is carried out. The materials are melted, transformed into thin strands, and passed through a conveyor belt into a chamber with cold water. After cooling and solidifying, they are cut by shredders into very small granules.

8. After the materials are granulated, the production of new plastic pallets begins.

9. Recycling plastic pallets is considered one of the simplest recycling solutions, as it can be carried out using only a plastic grinding machine.

In this article, we briefly reviewed the stages involved in recycling industrial and plastic pallets. Recycling pallets not only helps protect the environment but also leads to the production of new products. Although second-hand palettes are obtained through the recycling process, they maintain their original quality and performance and cause no problems in the process of loading and transport.

In general, purchasing plastic pallets offers many advantages, including high quality, recyclability, reasonable price, good hygiene, resistance to water absorption and contamination, and more. When buying pallets, it is important to consider their dimensions and size to ensure they can bear the weight of your load. In addition, whether new or recycled, pallets must be compatible with your packaging system and handling equipment.

Dear customers can contact the Persian Sanat support team in case their pallets or box pallets are damaged and take advantage of the recycling service and the delivery of new products.