Want to know more about process of manufacturing plastic pallet? Follow us throughout this article to learn how different machines work, specifics, benefits and their method of use.

In nowadays business world, which pace and efficacy in logistics chain speaks first, choosing the right mean for transportation and storage is of importance. Pallets play a key role in bridging between manufacturer, warehouse and distributor in transporting different goods. In a few past decades with wooden pallets being the only choice of consumers, the perspective has changed toward modern substitutions cause of difficulties in hygiene, humid-resistibility and rigidity in exportation rules.

Plastic pallets are the new substitution. Having longer durability and lifespan, they can be produced by recyclable material, all of which are compatible with food and pharmaceutical industrial rules. The core for this innovation lies beneath the machinery in producing plastic pallets; machines that with advanced technology can turn raw material into a world-class strategic product for logistics.

Devices discussed are not merely some industrial machines, but an interconnection between technology, economics and bio-sustainability has led to creation of these wonders. In the following we will introduce you to variety of machines and techniques shaping the future of production and warehousing.

While traditional techniques often involve handwork and instability, automated machinery has made the process fairly automatic, improving quality as well as efficacy. With automation involved in pallet production industry, the speed, precision and quality has increased significantly and the need for human intervention has been minimized. Variety in producing plastic pallets and boxes, along with precise measurements are benefits of using these modern devices.

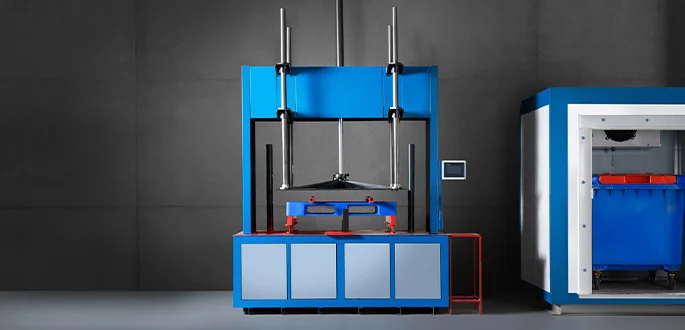

The main parts of these machines consist of a hydraulic system for power supplement, which guarantees quick reaction, energy saving and efficiency, an electric system with PLC for controlling along with a mold which gives shape of a pallet to molten plastics. These machines automate production of durable and sustainable pallets for logistics and warehousing and also offer an eco-friendly technique for recycling plastic waste.

Choosing the type of device depends on the production capacity, type of target market, starting capital and raw materials. In general, manufacturing plastic pallets and box pallets includes three techniques of Injection Molding, Thermoforming and Rotational Molding.

In the following, we will discuss different types of plastic manufacturer devices.

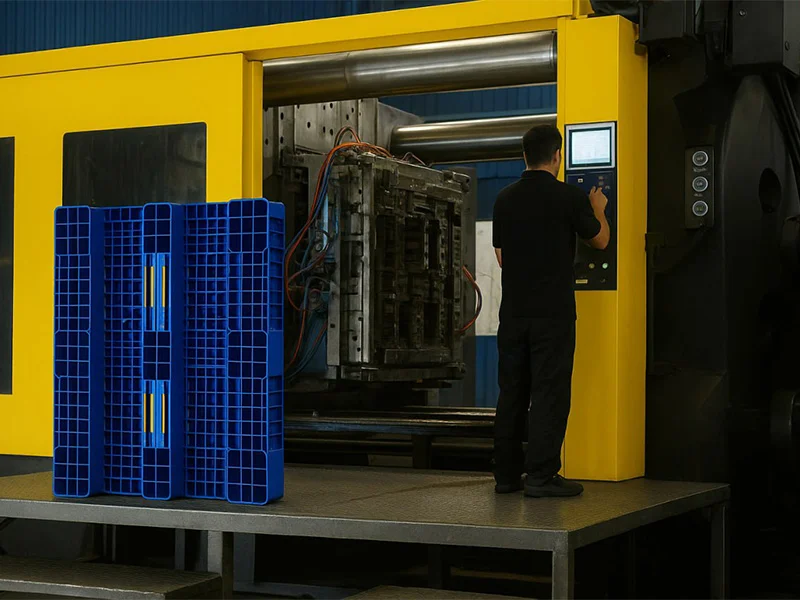

☑Injection Molding Machine

- Injects molten plastic with high pressure into mold.

- Used in manufacturing pieces like plastic pallets, containers, vehicle parts and toys.

☑Thermoforming Machine

- Plastic sheets given heat becomes soft and mold with air pressure or suction.

- Proper for light-weight and low-expense products like trays, packaging containers and light exportation pallets.

☑Blow Molding Machine

- In this technique, molten plastic gets into mold as tubes, then by blowing air, plastic will stick to lining of the mold, getting its shape.

- Usually used to manufacture bottles, barrels, plastic tanks and light-empty plastic pallets.

☑Compression Molding Machine

- Powder or granular substances under heat and pressure get molded.

☑Rotational Molding Machine

- For manufacturing big empty products such as water tanks and some pallets and box pallets.

Injection Molding is the most common method in manufacturing plastic pallets which allows producing pallets with variety of designs yet precise, being the appropriate choice for heavy industrial pallets with large numbers. This method requires expensive molds and powerful injecting devices. These machines are equipped with hydraulic or electric systems and require large spaces and high starting capital.

Thermoforming Method in comparison with the Injection method, has less expenses and fits better with producing light, economic pallets. Along with smaller size and lower expenses, these devices have less maintenance cost as well.

While in Rotational molding method the pace of production is slower than the Injection method, the opportunity of building more durable products takes place.

Types of produced pallets

- Stackable: save space

- Rack: apt for heavy loads

- Nestable: taking less space while unused

- Block & Stringer: offering different capacities

In modern world, plastic pallets aren’t just a transportation mean, but part of the strategic logistics chain and its optimization. Variety in methods of production proves that each industry can use this mean meeting their special needs, budget and type of product.

An advanced technique like Injection molding provides manufacturing heavy, durable and standard pallets; while techniques like Thermoforming or Blow molding brings the opportunity to build light and economic pallets. This resiliency in choosing the type of machinery and technique is an important benefit for manufacturers.

Using recycled material not only lowers the expenses, but also takes an important step in saving the environment and industrial sustainability. Future of this industry is bright considering the growing electronic businesses, hygienic rigidity in food and pharmaceutical industries and the need for safer transportation.

In conclusion, choosing the right device for producing plastic pallets is not only a technical decision, but an economic and strategic one that can change the view of a business.

Persian Sanat using state-of-the-art technology accompanied by advanced Injection devices has always lived to bring producers the most suitable products of their needs, meeting the latest global standards.