Plastic pallets, as one of the key components in the supply and transportation chain, play a critical role in handling, storing, and preserving goods. Since these pallets are required to bear heavy loads and withstand various physical and environmental conditions, ensuring their quality, safety, and durability is essential. This objective is achieved through the implementation of standardized tests.

In an industry where every second counts and any disruption can result in costly consequences, the quality of supporting equipment—such as pallets—is not merely a preference, but a necessity. Plastic pallets, as the invisible infrastructure of logistics, must maintain their functionality and durability under stress, impact, and uneven load distribution. Ensuring such performance is only possible through accurate and standardized testing procedures.

Why Do Pallets Require Standardized Testing?

At first glance, pallets may appear to be simple structures made of plastic, wood, or metal; however, in practice, they serve as the backbone of industrial logistics. Pallets are expected to bear heavy loads under highly challenging conditions—from uneven warehouse floors to the continuous vibrations and shifts inside trucks, or localized pressures from multi-tiered stacking. Even the slightest flaw in design or raw materials can lead to significant financial loss, distribution failures, or even injury to personnel.

In such demanding contexts, the only reliable way to ensure a pallet’s performance is through standardized testing and evaluation. These tests are not merely laboratory checks; they are realistic simulations of the mechanical stress and fatigue that pallets must endure in real-world scenarios. Standards act as a common technical language among manufacturers, buyers, and regulatory bodies—a trustworthy framework that renders performance measurable and quality verifiable. Without these testing protocols, no engineering, economic, or safety assurance can be claimed for a pallet.

The forces exerted on pallets throughout their lifecycle vary greatly, depending on usage conditions. The test methods described in international standards offer approximate simulations of actual pallet use. These tests assist pallet designers in establishing an optimal trade-off between cost and performance at the design stage.

The advantages and significance of standardized testing for plastic pallets can be summarized as follows:

Transportation and storage safety :

Inadequate pallets may break during handling or stacking, potentially causing product damage or injury to personnel.

Performance reliability:

Tests such as bending, shear, and impact resistance evaluations determine whether a pallet is suitable for specific load and environmental conditions.

Product comparison and selection :

Standardized testing allows for objective comparison between different pallet types in terms of quality and performance.

Compliance with export/import regulations :

Meeting national and international standards—such as ISO—is often a mandatory requirement for access to global markets.

Legal and Regulatory Basis for Pallet Testing

According to the Iranian National Standard INSO 16585-1, initially ratified in 2014 (1393) and revised in 2023 (1402)—which is based on the international standard ISO 8611-1:2011—pallet testing protocols have been established to ensure functional performance and reliability. This standard has been formally approved by the Technical Committees of the Institute of Standards and Industrial Research of Iran (ISIRI) and is legally binding.

As stipulated in the Law for the Amendment of ISIRI Regulations (ratified in 1952 / 1331), the testing and certification of pallets falls under the sovereign responsibilities of ISIRI and applies to both domestically manufactured and imported products.

Classification of Standard Pallet Tests

According to INSO 16585-1, the standardized tests are classified into three main categories:

a) Nominal Load Test

Determines the safe and continuous load capacity of the pallet.

Essential for selecting and designing pallets based on expected operational loads.

b) Maximum Working Load Test

Assesses the actual load-bearing capacity of the pallet up to the point of failure or significant deformation.

Suitable for simulating extreme industrial usage conditions.

c) Durability and Service Life Test

Evaluates the long-term performance of the pallet under repeated loading, humidity, impact, and other environmental stressors.

Types of Specialized Tests Performed on Pallets

According to the referenced standard, a comprehensive set of tests is conducted to evaluate pallet performance, including:

Bottom and deck bending test

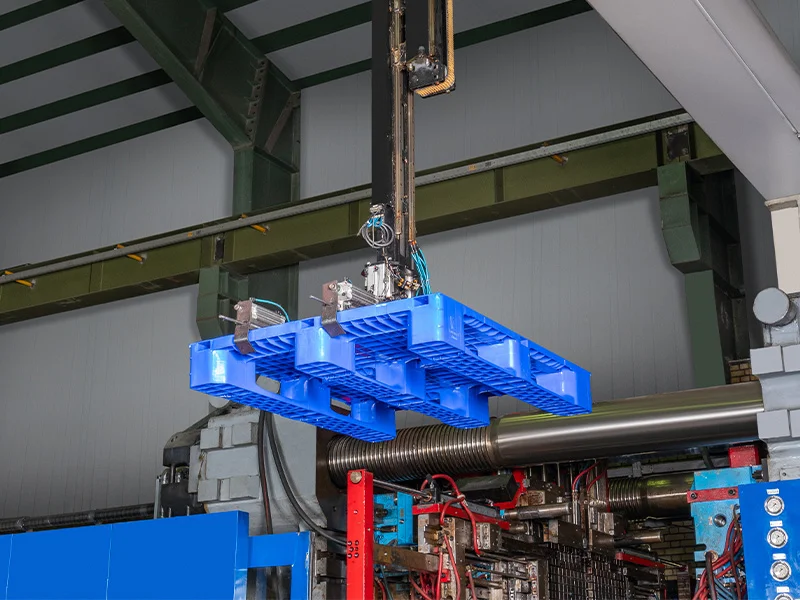

Forklift handling test

Compression test on blocks and supporting beams

Impact test on pallet edges, corners, or center

Drop test from a specified height

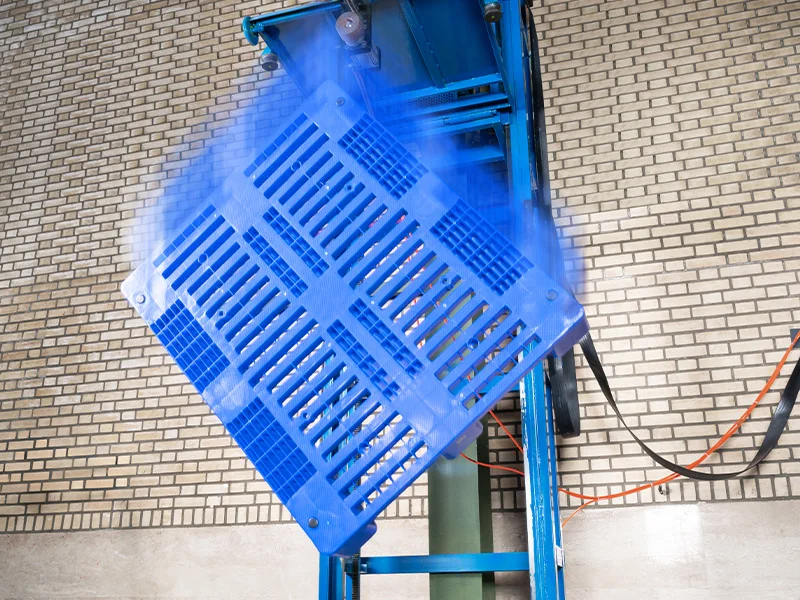

Static and dynamic shear tests

Coefficient of friction and slip angle test

Airbag test to simulate distributed load conditions

Using standardized testing for plastic pallets not only guarantees safety in transportation and warehousing, but also holds significant legal, commercial, and technical importance. Adhering to these standards enhances market confidence, reduces failure risks, and improves the overall quality of supply chain services.

Standardization and rigorous testing of these pallets are not merely legal obligations or formal procedures, but rather strategic investments in maintaining quality, minimizing hidden costs caused by failures, and reinforcing trust across the supply chain. Such tests ensure that pallet design and production are based on empirical data and real-world operational conditions, rather than theoretical assumptions.

Ultimately, compliance with established standards is the only reliable basis upon which manufacturers, end users, quality inspectors, and regulatory bodies can make informed decisions. In a competitive global landscape, quality is never accidental; it is the result of systematic testing, evaluation, and adherence to professional benchmarks.

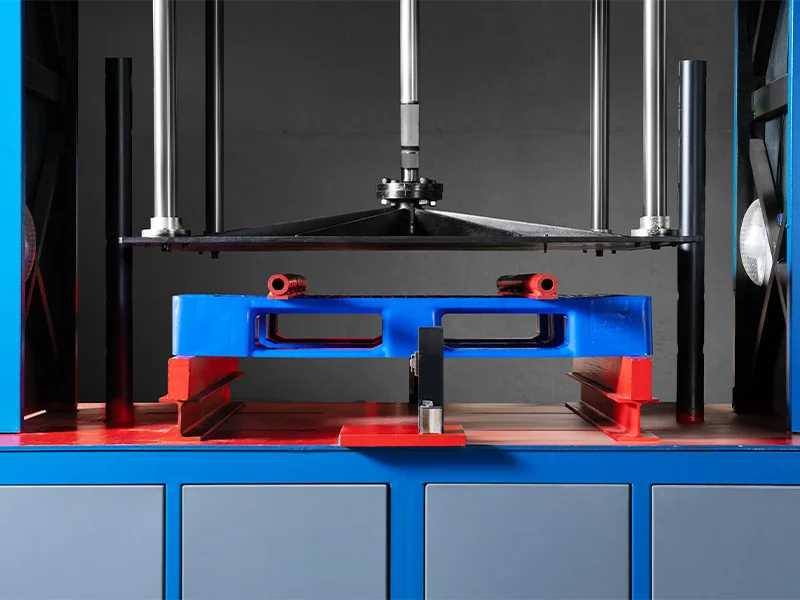

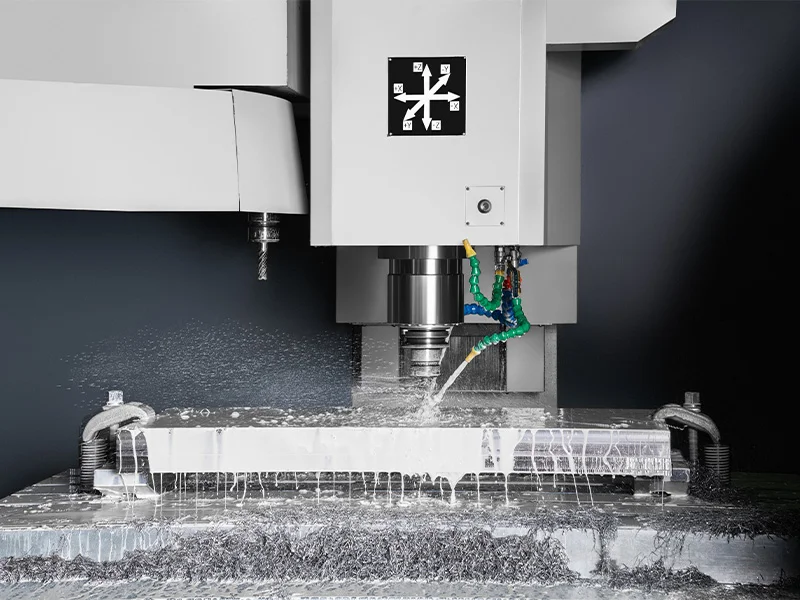

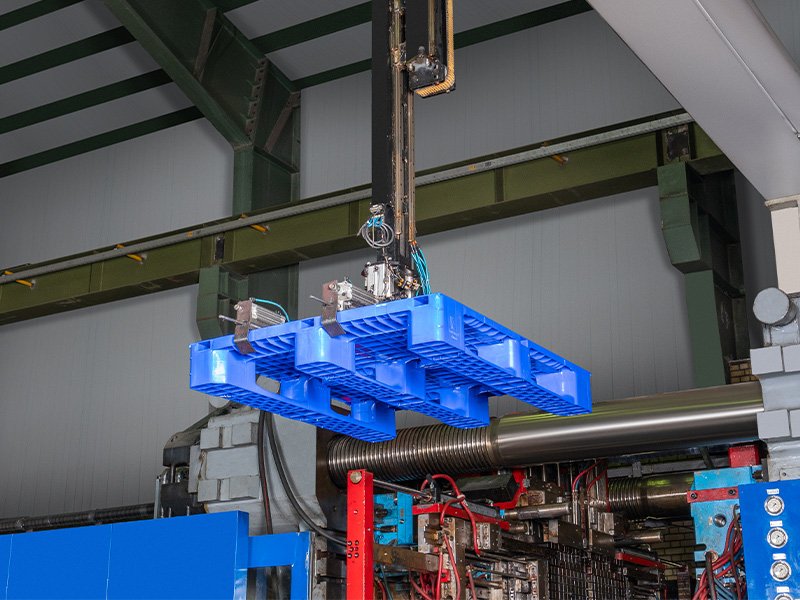

In line with this vision, Persian Sanat Co., a leading manufacturer in the field of industrial pallets and box pallets, has adopted a strategy beyond conventional requirements. By launching a state-of-the-art testing laboratory, the company subjects all its products to a comprehensive range of technical, mechanical, and performance tests before entering the market—tests designed in accordance with the latest national (INSO) and international (ISO 8611) standards.

In this lab, indicators such as bending resistance, base strength, impact tolerance, forklift testing, load distribution, storage conditions, and drop resistance are thoroughly assessed to ensure that every pallet or box pallet enters the logistics cycle with complete confidence. These procedures are carried out using precision instruments under the supervision of technical teams and trained experts.

Persian Sanat’s commitment to quality goes beyond testing its own products. By recording and documenting all test results, the company enables performance evaluation and traceability for every production batch. This means that buyers receive not only a durable product, but also a technically backed and verifiable guarantee for use in high-demand industrial settings.

This rigorous and science-driven approach has made Persian Sanat the top choice for major industries—including food, pharmaceuticals, petrochemicals, and automotive—both domestically and internationally. In today’s world, where trust is the most valuable asset, we take pride in the fact that Persian Sanat builds it through testing, analysis, and unwavering commitment to standards.